Switches and relays are generally used for the initiation and control of aircraft circuits. The different types of switches have been described below.

TOGGLE SWITCHES

Toggle switches are one which have large gap between make and break position. A toggle switch can be two position switches i.e. on or off or it can be a multi position switches sprung biased to the centre or off position. Spring biased switch are to be pressed and held for their operation in desired direction.

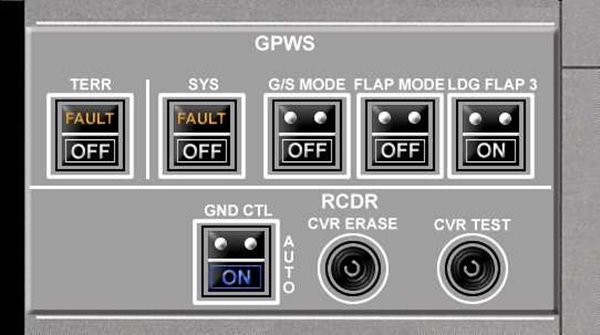

SWITCH LIGHTS

Switch lights consist of largely superseded toggle switches in the modern aircrafts and they combine the functions of a switch with a push action and an indicator light for the associated function.

There are two basic types of Switchlights:

Momentary Action: Where you have to press and hold to activate and release to deactivate.

Alternate action: Where you have to press and release to activate and press and release second time to deactivate.

There is an indicator in the lens which confirms the selected position and provides a warning which requires the switch to be selected.

GUARDED SWITCHES

These are toggle switches or switch-lights that can be guarded to prevent any inadvertent operation for example Generator disconnect or fuel dump master. Refer the diagram given below.

MICRO SWITCHES

Micro Switches describe the small movement between the make and break position. They are generally used in aircrafts’ doors but are now these days being replaced by proximity sensors. They activate indications on the flight deck or control relays for a sequenced operation. Nowadays micro switches are largely replaced by proximity detectors.

BI-METALLIC SWITCH (THERMAL SWITCH)

These switches are temperature sensitive and get activated whenever a threshold value of temperature is reached. This indicates to the pilot whether to activate or deactivate a circuit. For example fire detection circuits, oil temperature warning light and battery overheat switch.

PROXIMITY DETECTORS

Proximity detectors are electrical or electronic sensors which usually respond to the presence of material. This electrical or electronic response is used to activate a switch, transistor or a relay. There are different types of proximity detectors, some of the popular ones are

- Inductive Type

- Capacitive Type

- Magnetic Type

The inductive and magnetic ones need the monitored material to be metallic, but the capacitive detectors can monitor both metallic and non-metallic materials.

Inductive Type

Such types of sensors have an inductance coil whose inductance changes whenever a ferromagnetic material is brought in close proximity to the sensor. Such sensors are used in undercarriage systems in the place of 2 micro switches.

Every proximity switch comprises of three parts(given example is for landing gears)

- There is a printed circuit card located in the landing gear accessory unit.

- A sensor is located on appropriate landing gear structure.

- A target (or an actuator) for each sensor is located adjacent to its sensor.

Proximity sensor is a hermetically sealed unit that is actuated by the presence of target or the actuator (which means it is not touched by it). Thus, the proximity switch is usually unaffected by atmospheric conditions and this makes it a very reliable one.

Capacitive Type

In these types of sensors the detection is made by a capacitor that undergoes a capacitance change depending on the proximity of the material. These detectors are extremely versatile and are capable of detecting all materials, liquid and solid. They can also detect ferrous or non-ferrous targets, high or low liquid levels in a hydraulic or fuel system.

Magnetic Type

A magnetic coil that is situated in a magnetic field will have an electro motive force (emf) induced in it whenever the magnetic flux changes. The magnitude of induced emf generally depends on the rate at which the flux is changed. These are some of the basic principles on which magnetic proximity detectors operate.

A coil is usually wound around a bar magnet and one of the magnet is located close to a ferrous object. When the ferrous object moves the flux changes and an emf is induced in the coil. When a number of ferrous objects move past the magnet a train of pulses gets induced in the coil. You can spot magnetic detectors being used along with mild steel gear wheels, where each tooth in the wheel is a ferrous object. The detector is located radially and close to the periphery of the wheel. The detector provides an output that has a frequency equal to the frequency of passage of the teeth past the detector.

TIME SWITCHES

Time Switches can be initiated electrically or mechanically in order to activate a circuit after a specific time interval has elapsed. For example Auxiliary power unit air intake door closes 30 seconds after the APU shuts down.

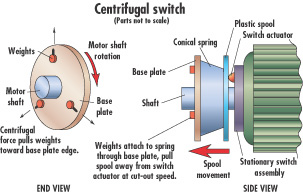

CENTRIFUGAL SWITCHES

Such switches can be set to activate or deactivate a circuit as the rpm of a device increases or decreases. For example Starter motor cut out switch.